1. In the process of cashmere making, the main source of waste gas is cashmere machine, and the types of waste gas vary according to different processes. Generally, the main waste gas is: sodium hydroxide and KOH in single crystal cashmere production, more NOx in polycrystalline cashmere production,and a small amount of HF and other waste gas.

Treatment process: four stage high concentration acid mist purification tower in series is used for high nitrogen oxide concentration, and sodium hydroxide and sodium sulfide are added for washing treatment; two stage acid mist purification tower in series is used for low nitrogen oxide concentration, and sodium hydroxide is added for washing treatment.

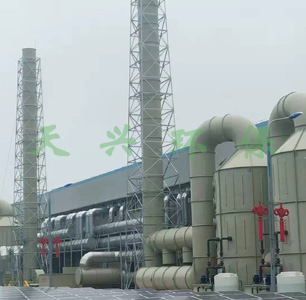

Main features: high purification efficiency, compact structure, corrosion resistance, aging resistance, automatic control, simple operation, widely used in solar energy, electronic semiconductor and other industries.

2. The equipment involved in the diffusion process is mainly: diffusion furnace, in which the acid waste gas is hydrochloric acid mist HCl and a small amount of chlorine gas Cl2. The main equipment involved in dephosphorized silica glass and etching process are etching machine and silicon wafer cleaning machine. The main acid waste gas generated is HF, CF4, SiF4, etc. acid mist purification tower is used and sodium hydroxide is added for washing treatment.

Main features: high purification efficiency, compact structure, good corrosion resistance, aging resistance, widely used in solar energy, electronic semiconductor and other industries.

Yixing Guodian photovoltaic

Lu'an, Shanxi

Hefei Tongwei Optoelectronics